How to Make a Thermal Fan Control

Summary

The fans in practically all modern desktop PCs are thermally controlled. This means that they are only turned on when needed, usually when the PC’s internal temperature gets too high. The fans can turn on when the temperature rises, moving hot air and replacing it with cooler air. Some PCs can even run the fans at different speeds, depending on the temperature.

Older PCs always had their fans running at full speed. Being able to control them means that noise is kept down and the wear and tear on the fans is minimised.

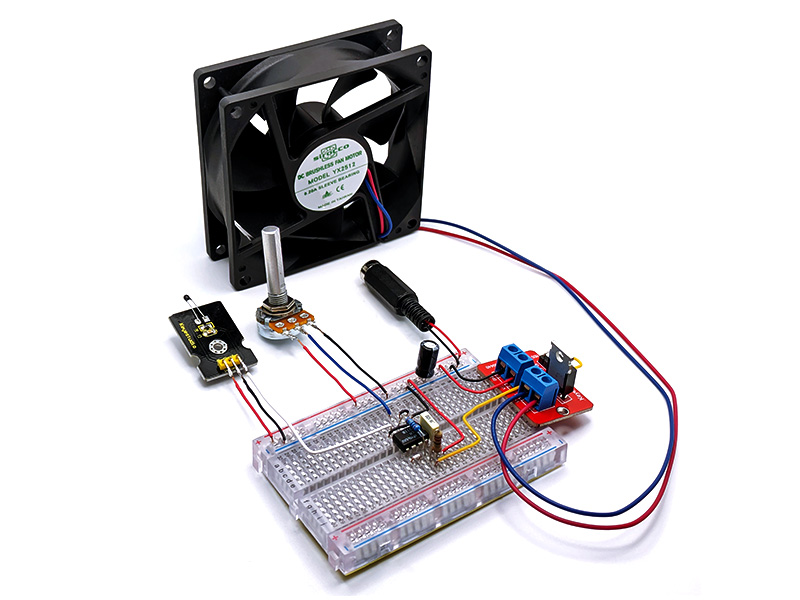

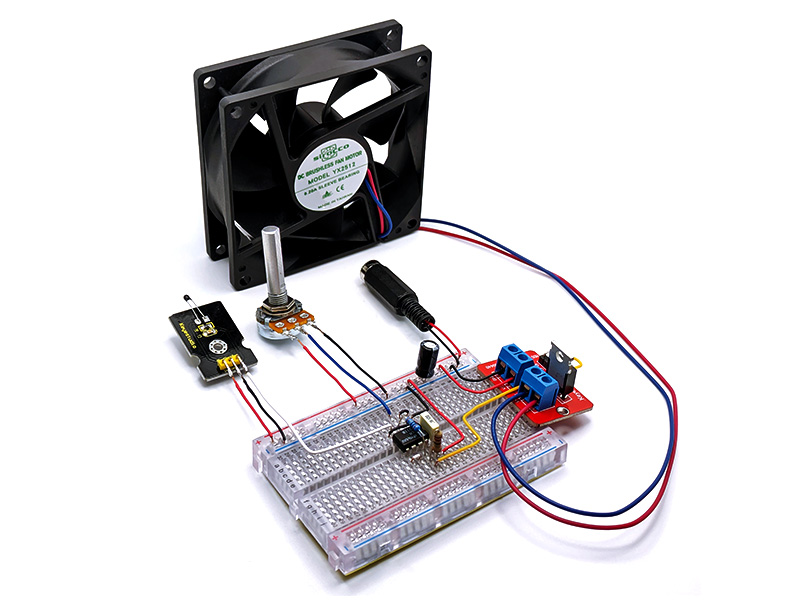

This project has a similar function; it provides automatic control of a fan based on temperature and can be adjusted to work at different temperatures, but it doesn’t require a microcontroller. It could be useful, for example, to power a ventilation fan in a room if the temperature inside that room gets too high.

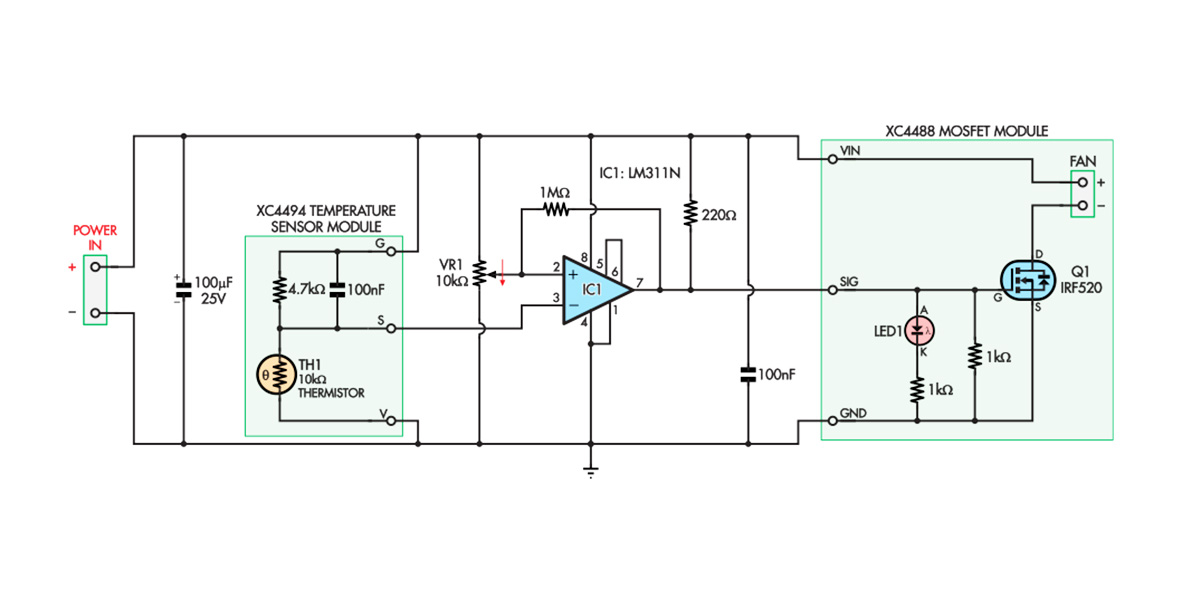

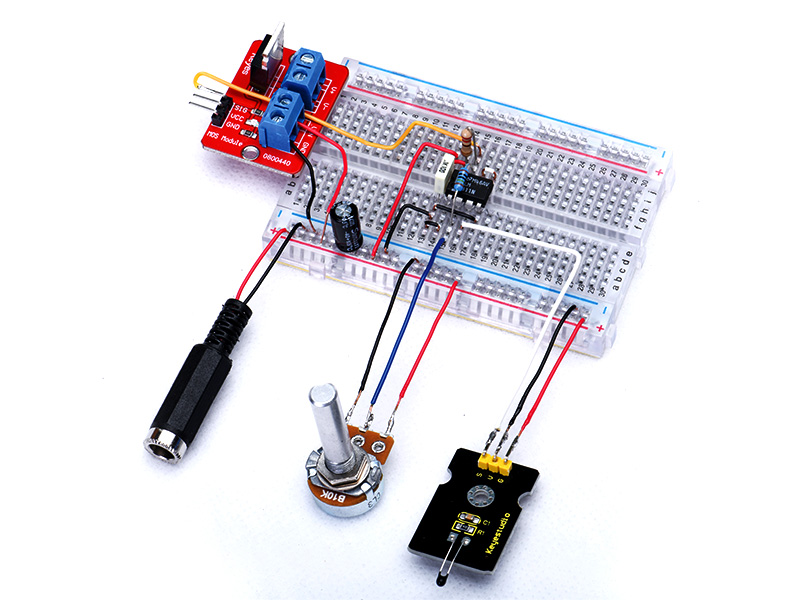

We use the Jaycar XC4494 Temperature Sensor Module to sense the ambient temperature and the Jaycar XC4488 Mosfet Module to switch the fan (or other low-voltage DC load) on and off.

The Temperature Sensor Module produces an analogue voltage that depends on the temperature. We apply that voltage to a simple comparator chip that produces a high or low level output, depending on whether the analogue voltage is above or below a set level.

Materials Required

| 1 | Duinotech Arduino Compatible 24V 5A MOS Driver Module | XC4488 |

| 1 | Duinotech Arduino Compatible Temperature Sensor Module | XC4494 |

| 1 | 80mm 12V DC Fan | YX2512 |

| 1 | 12V DC 500mA Power Supply 2.1mm DC Plug | MP3011 |

| 1 | Arduino Compatible Breadboard with 400 Tie Points | PB8820 |

| 1 | 2.1mm DC Socket with Screw Terminals | PA3713 |

| 1 | 10k Ohm Linear (B) Single Gang 16mm Potentiometer | RP7510 |

| 1 | LM311 Voltage Comparator Linear IC | ZL3311 |

| 1 | 100nF 100VDC MKT Polyester Capacitor | RM7125 |

| 1 | 100uF 25VDC Electrolytic RB Capacitor | RE6140 |

| 1 | 220 Ohm 0.5 Watt Metal Film Resistors - Pack of 8 | RR0556 |

| 1 | 1M Ohm 0.5 Watt Metal Film Resistors - Pack of 8 | RR0644 |

| 1 | 8 Pin Production (Low Cost) IC Socket | PI6500 |

| 1 | Breadboard Jumper Kit | PB8850 |

Table of Contents

Similar projects you may be interested in